Insights from the URGE network: thematic report

Edited on

21 May 2025Start small: The journey to scale. Experiences from the URGE: Circular Building Cities Network.

By Dr. Eleni Feleki, Lead Expert of the URGE Action Planning Network

Introduction

Too often we speak highly of an ideation process and its importance to take decisions. We focus on the co-creation part and we appreciate very much existing methodologies that we stakeholders’ groups can follow during an ideation process. Stages, like the divergent, convergent, part, fancy digital platform tools have replaced the traditional whiteboards and matrixes to identify and engage all relevant actors, are of great importance.

The question is, What do we do with these ideas? How can we really know that they are effective? How can we assess that theoretically? The truth is that ideas are of little use if they stay on a nice board. Their merits can be really evaluated (and valued) only in the case that they take flesh and blood, especially when others start talking about them. Putting an idea on the ground, in a way that its merit can be assessed, is definitely very challenging. The idea should be reframed into something specific, measurable, achievable, relevant and timebound. Questions like: How is this idea translated into something concrete? How will we assess it will be effective (enough)? Are there enough funds? Is it relevant enough to the visions and aspirations that it addresses? Are there time constraints? raise only after we decide to put an idea into practice.

People are usually afraid to commit to something concrete, as no one wants to fail. But, how do we define failure? Proving that an idea is not going to work on the real ground, is it really a failure, or a success? It is true, that a lot of ‘’good willers’’ will wait in the corner to put into question skills of people involved, design of the project and so on.

This is where small-scale experimentations can be put forth. Start small. This will be your journey to upscale. A small step towards bringing real change. Turning an idea into something concrete, working with whatever we have available and trying to be as creative as possible, will help improve and will smooth the road to upscale, or even, will call for a ‘’THIS mission: aboard – change the parameters - test again if needed’’. This is also a success. Maybe even a bigger one.

In the frame of the URGE: Circular Building Cities Action Planning Network that is financed by URBACT III Programme, 9 partners have committed to design integrated action plans, following a participatory approach with stakeholders and have them approved if possible, by politicians. These partners have a common ambition, to putting a stepping stone towards green transformation, through boosting circular economy practices, in the building sector. The local process was led by 9 inspired local stakeholders’ coordinators, committed to hold ideation process, keep stakeholder members engaged all along, co-decide on actions to be included in the local action plans and describe them in the most SMART way.

Taking advantage of the programme’s innovation, to provide the possibility to test an idea and refine the action plans, before their finalisation and approval, several URGE partners have designed small-scale activities. Small-scale activities are implementation-related activities dedicated to testing a new approach. Small-scale activities designed in the frame of URGE, are addressing the local vision, are part of the integrated local action plan, are designed building upon transnational exchange of knowledge and experiences and aim to achieve intelligence, through lessons learnt to better prepare for scaling up. This article illustrates small-scale activities undertaken by the City of Munich, REA (Riga Energy Agency – part of the City of Riga) and Nigrad d.o.o. Another article will follow soon, illustrating small-scale activities of the City of Kavala and Granada.

Talent in Munich

Even though Munich does not formally implement a small-scale using budget from the Programme, there is a side mini-project in the context of the “Bayernkaserne” project, that meets the requirements and serves as a test balloon, playing and experimental field.

The Bayernkaserne project

The Bayernkaserne project is a hard investment that will serve to raise awareness, train and educate a lot of actors around the construction chain. The broad vision is to upscale this project’s results into a strategy, establishing the concept of circular economy in all construction projects in the city of Munich. In the course of this project, the city of Munich plans to recycle, reprocess if needed and reuse materials coming from deconstruction. Demolition material will be mostly used as a supplement for the production of R-concrete and for various substrates. Studies, in view of using recycled materials have shown that the use of recycled materials in road construction and landscaping meets the standards. Attention needs to be paid to include the studies’ outcomes in order to enable the reuse of materials for new constructions. One mean to achieve that, put also forward in the City of Munich, is the inclusion of circular economy criteria in municipal procurements. More measures have been investigated by the group of local stakeholders (URBACT Local Group), always studying the case of the Bayernkaserne project.

Figure 1: Bayernkaserne project in Munich (City of Munich)

Although the Bayernkaserne project had been planned before the kick starting of the URGE project, the URBACT participatory approach was adopted both at the local level but also at transnational level, ‘’feeding’’ URGE partners with knowledge and vice versa.

The basic elements of the roadmap to achieve the aim

Munich aims to boost the use of 100% recycled concrete in building constructions, which requires time and a lot of effort. The elements that were clear from the beginning were the following:

- The role of the City towards this transition is of overarching importance and for this reason, a municipal property has been chosen to hold experimentations: the Bayernkaserne former military area, owned by the Municipality

- The need to reassure that the new material (R-concrete) is safe for reuse in new constructions. For this reason, a laboratory was set up in the Bayernkaserne area, where different mixtures were tested, to come up with the appropriate recipes. The close collaboration with the University of Applied Sciences of Munich and with technicians was fundamental.

- Raising awareness and building early trust with the market, constructors and builders, is critical. For this reason, as soon as the first tests’ results were available, proving that R-concrete concentrates the appropriate specifications to be safely reused into construction projects, an informative session with the biggest market players was realised.

- The need to institutionalise the change. For this reason, a City Resolution has been drafted and is submitted for approval by the City Council. The City Resolution states clearly that new building constructions put forward by the Municipality

,need to use R-concrete. This requirement will be placed also in the municipal tenders. Achievable, realistic targets in terms of the quota of R-concrete that will be required to be embedded in the construction projects as a requirement in the tenders, is currently under decision. - The need to build trust with the smaller building companies. Smaller building companies and individual builders are persistent to the change as they fear that the new material might not be appropriate for specific parts of the construction process. More than that, they fear that they will not be able to find recycled concrete and comply with the new specifications/requirements of the municipal tenders.

With the approval of the City Resolution and the tests proving that 100% recycled concrete is appropriate for use in construction projects, an important step to influence regulations at national level will be achieved.

While the City Resolution is being finalised and till its final approval in May 2022, the URGE URBACT Local Group has brilliantly decided to put forward a smaller scale experiment, withing the Bayernekaserne project, in order to deal with the needs to build trust, raise awareness and provide a visible and realistic example that a construction can be built, using R-concrete.

This small-scale experimentation has been implemented with the involvement of Munich University and its students, to dispel the concerns of developers and contractors, while also students have been provided with hands on experience and practical knowledge.

This small-scale experimentation has been implemented with the involvement of Munich University and its students, to dispel the concerns of developers and contractors, while also students have been provided with hands on experience and practical knowledge.

The small-scale action of Munich: Construction with R-concrete produced out of 100% recycled aggregate

In practice, architecture and civil engineering students at Munich University, under the supervision of Prof. Dr. Andrea Kustermann, Prof. Thorsten Stengel and Prof. Christoph Dauberschmidt, Faculty of Civil Engineering, and Prof. Arthur Wolfrum, Faculty of Architecture, jointly built a sample pavilion with a floor area of 20 m². This consists of R-concrete with 100% percent recycled aggregate. The pavilion demonstrates the range of design possibilities of R-concrete. The interdisciplinary groups of civil engineering and architecture students designed and built 4 columns, with different surface structures, illustrating the design possibilities from rough to fine, plastic, playful or strict.

Figure 2: Small-scale action in Munich: sample pavilion of R-concrete (City of Munich)

How to succeed by daring to fail: A brave example from Riga

Riga is the capital of Latvia, home to 614,618 inhabitants, which is a third of Latvia's population. A beautiful city that possesses a lot of unused buildings and spaces. The old Town of Riga has beautiful, but old buildings that are in need of renovation. Riga envisions to boost circular economy and is one of the most active partners of the URGE Network, in terms of undertaking and implementing actions already during the life time of the project.

The small-scale action of Riga: An exchange point for construction materials

One of the overarching needs that have been identified by Riga Energy Agency (REA), partner in the URGE project, is the lack of a point, where people can leave and/ or retrieve building materials in order to reuse them, mostly in small renovations: A materials’ exchange point. The seed was planted through the transnational exchange meetings, where the establishment and operation of material exchange points was transferred as a good practice, from the City of Copenhagen, partner city in URGE, as well as from the City of Oslo, partner in a ‘’sister’’ URBACT Network, Resourceful Cities.

Riga decided to test the operation of an exchange point, for building materials in order to assess the feasibility to upscale this action. In parallel, guidelines for the replication of materials’ exchange points have been developed.

The aim and benefits

The aim of the exchange point is to promote the sustainable use of construction materials, thus reducing both construction waste and the extraction and consumption of new resources. Exchange points allow consumers to receive the required materials in exactly the required quantity free of charge or at an affordable price. Such construction material exchange points help to use resources sustainably, relieve the waste management system, protect the environment and fulfill their social function. Exchange points promote a change in the habits of the population and are an important component of the infrastructure of the circular economy, which enables every citizen to implement the concept in their daily lives. Such points also reduce inequalities and help the most vulnerable groups in society to improve their living conditions. The operation of such exchange points may be based on different operating principles.

The implementation of the first building materials’ exchange point in Riga has been tested in the frame of the URGE project. This activity coincides with the tasks of the Latvian Action Plan for the Transition to the circular economy and supports the local Integrated Action Plan, introduced in the frame of URGE.

Figure 3: Small-scale action in Riga: exchange point for construction materials (Riga Energy Agency)

Citzens have been part of the experiment from the early beginning

The implementation of this small-scale activity, was launched at the end of 2020, with a survey of citizens to find out their views and expectations from the establishment of an exchange point for building materials. It was concluded that such an exchange point was not only theoretically useful, but even highly anticipated by the citizens. Many valuable suggestions for the implementation the exchange point were also received.

At the beginning of 2021, the URBACT Local Group gathered to analyse and plan the implementation of this small-scale activity through different scenarios.

The role of the NGO: FREE RIGA

Until 31 August 2021, FREE RIGA association installed and managed the first exchange point for building materials in Riga, at its premises at Viskaļu street 36. They also developed a visual identity and a website. The main findings lead to the introduction of guidelines for the establishment and operation of such exchange points elsewhere.

Limitations and drawbacks

During the implementation of the small-scale activity, several limitations and difficulties encountered and the managers had to adapt to the situation and change the initial settings. For example, the initially planned inventory of materials that would be available at the exchange point's website, proved unfeasible due to the wide variety of materials. There was an intention to also set up temporary repair services, a rental point, organise workshops, but such possibilities were explored without practical implementation, both due to the limitations of the pandemic and to the need to provide the premises with appropriate adaptation and safety instructions, which required for additional investments. However, these limitations did not hamper the establishment and operation of the materials’ exchange point.

Raising interest at national level

The small-scale activity received great public recognition through REA and FREE RIGA information channels, but did not reach a very wide audience at first. Later, nationwide media such as Latvijas Radio 1 and TV3 were involved, as well as Riga's largest house manager, Rīgas namu pārvaldnieks LLC, which placed information about the exchange point for building materials and repair tools at the monthly management invoices, delivering it to 100,000 mailboxes. During the trial, the exchange point gradually gained more and more public response. At least 2 months after the closure of the exchange point, residents continued to call the exchange point, wanted to use its services, and expressed the need to keep the exchange point permanently.

Figure 4: Exchange of construction materials in Riga (Riga Energy Agency)

Exemplary use of Cohesion Policy funds from Maribor, addressing the local circular economy strategy

Nigrad doo, is the only industrial partner of the URGE Network and is in close collaboration with the Municipality of Maribor to boost circularity in the building sector. Nigrad is also a partner at the CINDERELA project (H2020), where a pilot production plant to produce secondary raw materials, is established. With this pilot production plant, the project aims to demonstrate the technical, technological, and administrative possibilities of processing and using various non-hazardous construction waste as well as some other waste types to produce more sustainable construction products.

Following the pilot production and the lesson learned during the CIDNERELA project, the secondary raw materials produced in the pilot construction plant are being applied for the small-scale activity of the URGE project.

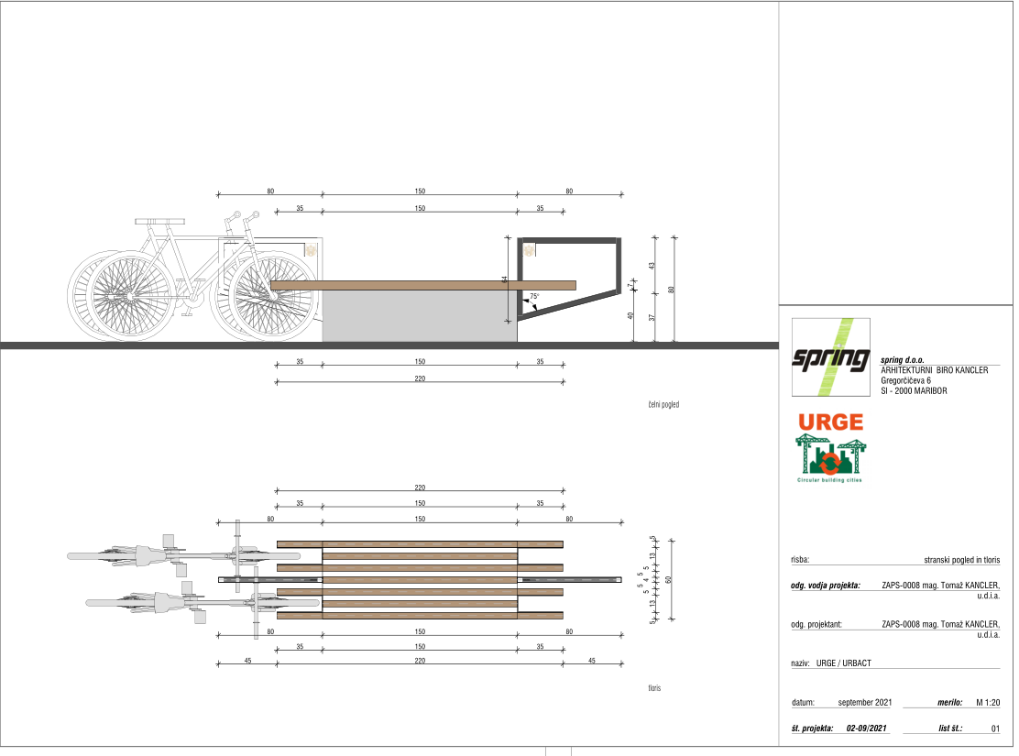

The small-scale action of Maribor: Micro-urban fixtures out of recycled aggregates

In the frame of the small-scale activity for the URGE project, Nigrad produces micro-urban fixtures out of recycled aggregates that can be used as benches with a bicycle rack.

Figure 5: Small-scale action in Maribor: production of micro-urban fixtures (Nigrad Maribor)

Figure 6: Technical drawing of micro-urban fixtures (Nigrad Maribor)

Benches combined with bicycle racks is a stylish and practical solution for decorating a city park, city centre or placing it near a school or a kindergarten. These benches will be made of recycled materials. Old benches, are deconstructed and the ‘’old’’ concrete’’ after tests, implemented in the pilot production plant, is transformed into ‘’green’’ concrete, used in the benches. Apart from concrete, reusable wooden parts and scrap out of metal profiles of the old bunches, are being tested and reused to form the new bench and its bicycle racks.

The message

Due to its characteristics, the architecture of a bench is interesting because it shows us lessons related to simplicity and the different possibilities to reuse. More than that, Nigrad aims to raise awareness and ‘’educate’’ citizens and market players on the potential uses of recycled materials. In the meantime, Nigrad is working closely with ZAG, which is a standardization institute situated in Maribor, holding tests of secondary raw materials and preparing for making them marketable products, safe and appropriate for upcycling uses.

Testimonies by small-scale activities’ key persons

“The URBACT methodology for integrated action planning helped us to systematise the approach that we knew from a theoretic point of view that we had to follow. Building integrated stakeholders’ group to co-design the action plan, was very helpful. More than that, participation in the transnational consortium of URGE gave us the great opportunity to benefit from sharing knowledge and experience with cities that face the same needs and have the same ambitions. That was helpful and engaging for our stakeholders’’ Daniel Rank, Munich URBACT Local Group Coordinator

“The URBACT methodology for integrated action planning helped us to systematise the approach that we knew from a theoretic point of view that we had to follow. Building integrated stakeholders’ group to co-design the action plan, was very helpful. More than that, participation in the transnational consortium of URGE gave us the great opportunity to benefit from sharing knowledge and experience with cities that face the same needs and have the same ambitions. That was helpful and engaging for our stakeholders’’ Daniel Rank, Munich URBACT Local Group Coordinator

“I highly appreciate the methodology of the URBACT programme, because it helped to bring the most important stakeholders at the table and provided with essential tools for the development of the Integrated action plan. For the city of Riga URGE has been an amazing source of inspiration and ideas for the transition to the circular economy. We learnt experiences from partner cities and gathered knowledge from experts involved in the project to support the development of the integrated action plan and its implementation. Implementation of the small-scale activity (Construction Material Exchange Point) gave us confidence that this is a must-have facility in Riga. We learnt that there are much more constraints and difficulties to overcome that we couldn’t predict before. This piloting will let us avoid costly mistakes that could lead to failure on a larger scale. All our lessons learnt are gathered in the concept note that is free to use for anyone across Latvia who wants to develop something similar.”, Ieva Kalnina, Riga Energy Agency URBACT Local Group Coordinator

“I highly appreciate the methodology of the URBACT programme, because it helped to bring the most important stakeholders at the table and provided with essential tools for the development of the Integrated action plan. For the city of Riga URGE has been an amazing source of inspiration and ideas for the transition to the circular economy. We learnt experiences from partner cities and gathered knowledge from experts involved in the project to support the development of the integrated action plan and its implementation. Implementation of the small-scale activity (Construction Material Exchange Point) gave us confidence that this is a must-have facility in Riga. We learnt that there are much more constraints and difficulties to overcome that we couldn’t predict before. This piloting will let us avoid costly mistakes that could lead to failure on a larger scale. All our lessons learnt are gathered in the concept note that is free to use for anyone across Latvia who wants to develop something similar.”, Ieva Kalnina, Riga Energy Agency URBACT Local Group Coordinator

“ The URBACT methodology for integrated action planning helped us to systematise the approach that we knew from a theoretic point of view that we had to follow. Building integrated stakeholders’ group to co-design the action plan, was very helpful. More than that, participation in the transnational consortium of URGE gave us the great opportunity to benefit from sharing knowledge and experience with cities that face the same needs and have the same ambitions. That was helpful and engaging for our stakeholders’’ Nuša Lazar, Nigrad d.o.o. URBACT Local Group Coordinator

The URBACT methodology for integrated action planning helped us to systematise the approach that we knew from a theoretic point of view that we had to follow. Building integrated stakeholders’ group to co-design the action plan, was very helpful. More than that, participation in the transnational consortium of URGE gave us the great opportunity to benefit from sharing knowledge and experience with cities that face the same needs and have the same ambitions. That was helpful and engaging for our stakeholders’’ Nuša Lazar, Nigrad d.o.o. URBACT Local Group Coordinator

Further reading

Bayernkaserne video: https://youtu.be/mZnALW8t1C4

Munich URGE Case Study: https://stadt.muenchen.de/dam/jcr:9156906d-05da-47a1-9ebb-79624912d1fa/Case%20study_Munich%20URGE.pdf

Riga video: https://youtu.be/sLezgOr-Rj4

website of the exchange point: https://www.remontmaina.lv/ -

Guidelines for the development of similar exchange point https://drive.google.com/file/d/1lDqAVy84j_I2eNXXV9tJow6btqzRV7uS/view

Acknowledgments

This article has been produced in the frame of the URGE APN, financed by the URBACT Programme. Special thanks to the team and actors from Munich, Riga en Nigrad d.o.o. for their valuable contributions, namely: Daniel Rank, Ieva Kalnina and Nuša Lazar.

Submitted by Anonymous on