Insights from the URGE network: thematic report

Edited on

21 May 2025Insights from the URGE Network and experience from the ‘’Bayernkaserne’’ pilot project: Regulatory and standardisation needs as drivers to foster circular economy in the building sector

By Dr. Eleni Feleki, Lead Expert of the URGE Action Planning Network

Background

Construction and demolition waste (CDW) is the largest waste stream in the EU by weight (Eurostat, 2019a). Construction and demolition is defined as a priority area in the EU according to the Circular Economy Action Plan (EC 2015) - one of the main blocks of the European Green Deal, Europe’s new Agenda for Sustainable Growth. The Circular Economy Action Plan announces initiatives along the entire life cycle of products. It introduces legislative and non-legislative measures targeting areas where action at the EU level brings real added value. The EU policy objectives for CDW management are:

- Prevention of CDW generation

- Reuse and recycling

- Reduction of hazardous substances in CDW

- Recovery of at least 70% of non-hazardous CDW generated

- Reduction of greenhouse gas emissions from the management of CDW

Moreover, the European Green Deal (11.12.2019) highlights that reaching the target of climate neutrality in 2050 will require action by all sectors of our economy, including the construction sector.

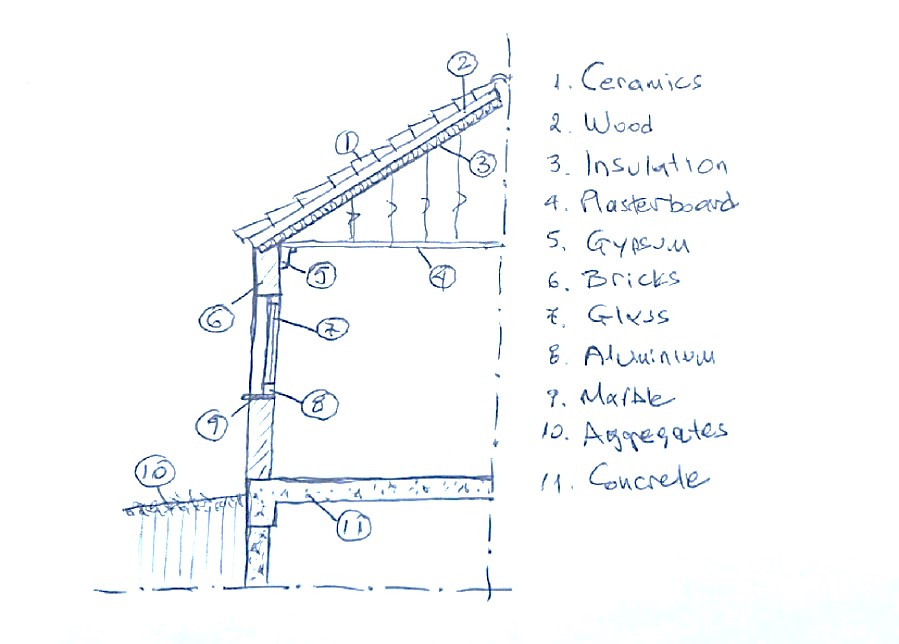

Figure 1: Bill of materials of a typical building (source: Nikos Chatzyvrettas)

Potential

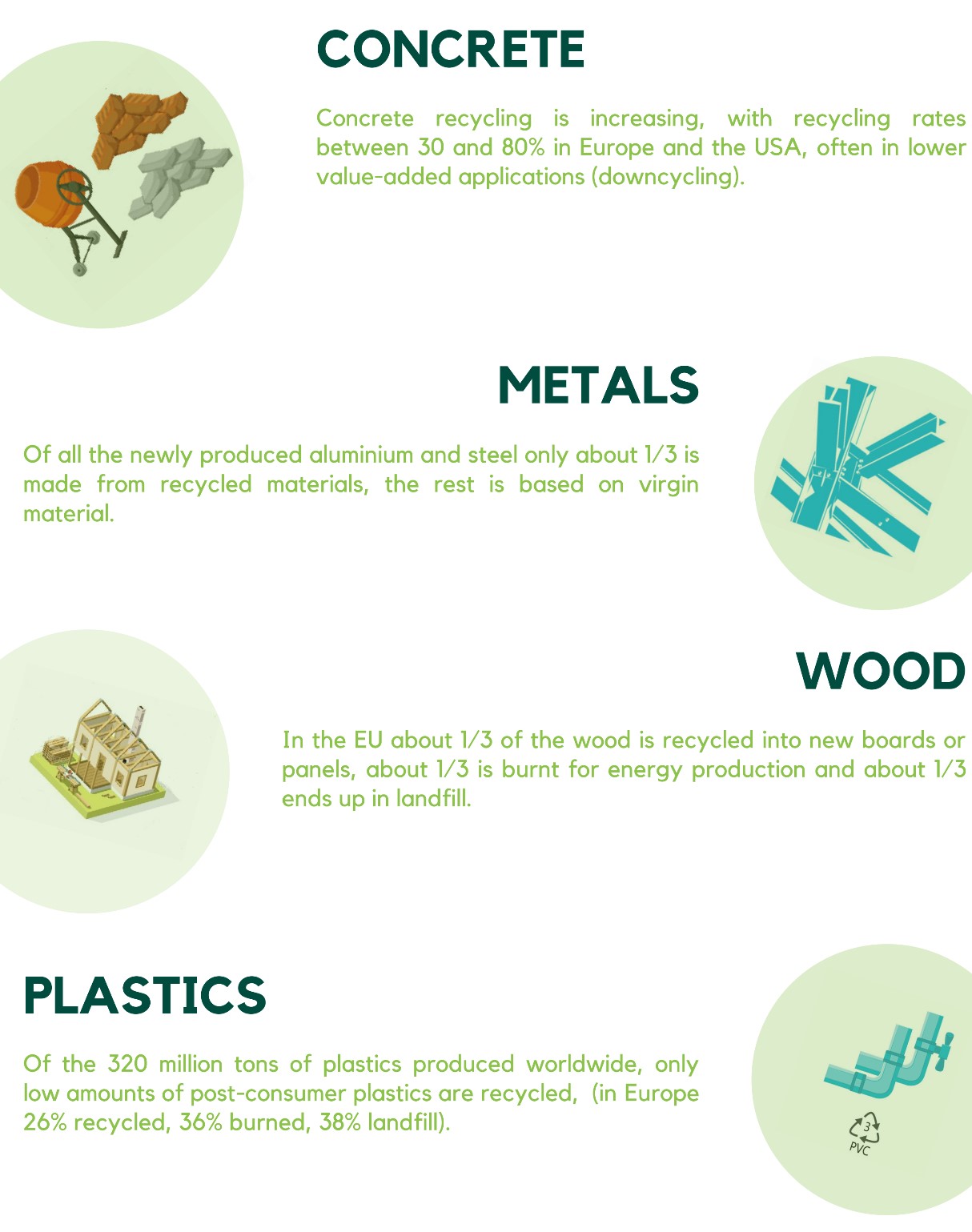

Significant fractions of recyclable, reusable materials are integrated in constructions in general and particularly in buildings. A typical bill of materials, is depicted in Figure 1. Although the recycling potential of CDW is high in quantitative terms, it is still under-exploited. The mineral fraction of CDW, for example, is currently mainly being used in road foundations (downcycled). The recovery performances differ significantly between EU Member States (Eurostat, 2019b). An overview of the current situation regarding the management of some of the most important construction material streams is depicted in the following infographic. Several tools are designed, such as:

- The Protocol for Construction and Demolition waste management is introduced as a non-binding guideline, fitting within the Construction 2020 strategy and within the Communication on Resource Efficiency Opportunities in the Building Sector

- EU Guidelines for audits before demolition of building

- Level(s): a common framework to assess the environmental performance of buildings

Infographic 1: Management of material streams in the EU (source: Eleni Feleki)

The framework that intensifies the need to use CDW in a circular manner seem to be in good order and tools are designed and introduced. However, what is needed to really to put it in action?

This thematic article tackles the regulatory and standardisation needs, as operational tools in order enable the use of secondary raw materials in the construction sector, always taking consideration safety issues. The concerns and the insights expressed in this article, come from the experience and transnational exchange of the URGE APN partner cities.

Issues that hamper the reuse of secondary materials linked to standards and regulations

Although introducing green criteria in procurements of products and service would seem to be a solution to boost the market of secondary materials use in the construction sector, this is not enough. Preparatory work is needed, to prepare the framework and enable their use to a larger extent. From an operational point of view, some of the obstacles are linked to:

- Lack of European technical specifications for the use of secondary raw materials

Even if ambitious goals are set and standards exist to some extent, goals cannot be met, if detailed technical specifications are not introduced. For example, some European standards, such as EN 206: Concrete – Specification, performance, production and conformity and EN 12620: Aggregate for concrete, allow the use of recycled materials in concrete. According to the EU regulatory framework up to 20% substitution of virgin aggregates with concrete waste is allowed, as this is not considered to lower the new concrete’s properties or influence its workability. However, the use of more than 50% of concrete waste raises the need for further testing (thus for new specifications) to prove the performance and the concrete is usually only suitable for certain applications leading to downcycling and not to upcycling. Undoubtably, the introduction of a full package of EU standards and technical specifications that would better reflect the EU targets needs piloting, tests, innovative solutions, so time and effort. Of course in this case, an alignment between European regulatory framework and reference to the new standards, would be required.

- Difficulties faced by Member States (MSs) to adopt to the demanding EU regulatory framework

National regulations follow the European regulatory framework. However, how ready are really all the MSs to adopt a demanding European regulatory framework that refers to new European standards? The readiness of the MS to adopt changes in the regulatory and standardisation frameworks and be aligned to the EU requirements varies. National regulatory framework updating is not an easy process. Undoubtably time is needed for the introduction, adaptation and in many cases transformation of current business models. Although MSs are in the process to adopt the EU ordinances and laws, there are still some gaps and the process depends on the prioritisation given at a governmental level. Different starting points, in terms of human capacities, materials and conditions that affect their quality, infrastructure, resistance to change existing business models, in combination with different governmental priorities are only some of the factors that can delay the transformation to a circular economy at country level and at EU level at the end. Thus, each MS’s case, needs special focus and action from the part of the EU if we want to achieve at the end the common goals.

For some materials and in some MSs progress has been made to introduce national standards and regulations to enable the use of secondary materials and replacement rates that go further than the current standards might be technically feasible, only if the appropriate measures are taken – selective demolition, adapted milling processes, extra processing of the aggregates, and/or adapted water management in the mix formulations. But are all MSs able to use this ‘’flexibility rule’’ and take these measures, in order to raise replacement rates and go further than current standards?

Concluding, there is still way to go by the MSs to adopt or harmonise their national standards and regulatory framework with the EU policy (demanding targets) and the (still voluntary) EU Directive on waste. National specifications, standards, national targets are missing or need updating.

In the frame of pilot projects held in several EU cities, tests are being conducted to investigate and validate that the specifications of products made of recycled materials are appropriate for certain uses. These tests offer valuable input towards the introduction of new or update of existing standards and regulations. Some progress is already recorded throughout the URGE Network.

Within URGE, partner cities have identified the importance of creating the necessary operational conditions to reuse CDW. The introduction of new or update of existing standards is definitely one of the lines of focus for the partnership. Below, the current situation and a pilot project is depicted, coming from the City of Munich which is one of the URGE partners.

The catalytic role of the introduction of new standards in the reinforcement of new legislation

Standards are technical documents, prepared by all interested parties (companies, consumers, workers, public authorities) on the basis of a number of principles (e.g. consensus, openness and transparency). Unlike regulations, they are not adopted by an authorised public authority but within private, independent and - in the case of European standards - officially recognised standards organisations.

Standards are a priori not binding and their application is voluntary. However, they can also play a catalytic role in the introduction of new legislation, in particular in technical regulations. If a legislator includes standards in a legal act or makes reference to them in one way or another, standards can obtain legal quality. The standards thus become a part of the requirements of as specific legislative act or of the system.

The advantages of making use of standards in legislation are manifold. Instead of being obliged to find solutions for difficult technical questions themselves, legislators can rely on the technical expertise of the standards developers and at the same time save public money. Moreover, thanks to the consensus-based, open and transparent procedure of setting standards and the subsequent broad acceptance of standards, the legislator can expect a broad acceptance of his legislation as well. Finally, standards reflect the latest ‘state of the art’ i.e. the latest technical developments. In order to follow the latest technical developments, standards must be regularly revised and accordingly adaptation of the legal needs to be done. The EU legislation may refer to international standards, European standards and, to a lesser extent, national standards.

Recycling of materials, under the angle of the Federal State Building Order in Germany: The case of recycled aggregates in structural engineering

The federal state Building Order in Germany, mainly consists of a Safety Law and not an Environmental Law. Thus, it is neutral with regards to the building materials. There is a generic requirement that materials have to be suitable for construction without harmful effects on health.

With regards to the recycling of concrete, the current normative requirements allow 25%-45% recycled aggregates in concrete up to a certain grade (C30/37). Asbestos in concrete structures, especially reinforcing bar spacers should be prohibited. Moreover, CDW containing asbestos may not be recycled.

At present, the use of recycled aggregates in structural engineering is very limited. Stakeholders have summarised them as follows:

- According to national legislation, only a small percentage of secondary raw materials (mainly concrete) can be used in the final product

- There is a lack of a Technical Standard, certifying the ability to use materials produced out of secondary materials and thus boosting the market

- Lack of circular criteria in procurements

Efforts to design new Technical Specifications for recycled concrete in Munich and reinforce legislation, through experimentation

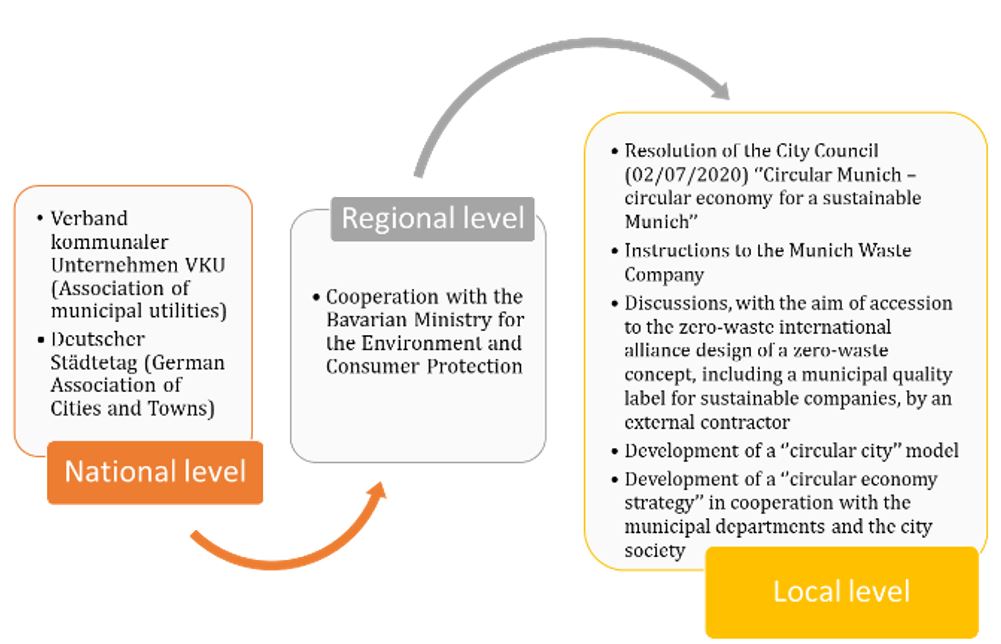

In the capital city, Munich, the need to treat CDW in a circular way is very much acknowledged and promoted. Efforts are being made to influence legislation, at all levels. Efforts are being made also to change the procurement process and include circular criteria.

Influencing legislation is never an easy task. Evidence is needed coming from real ground practices. Thus, in the City of Munich, the attempt to change legislation is based on a solid case coming from the Bayernkaserne pilot project.

Figure 2: Influencing legislation at all levels

The Bayernkaserne project

A first concept for the production of construction materials from recycled building rubble was approved by the City Council of Munich, in July 2018 and September 2019. This approval was issued only for the project in the Bayernkaserne area. The area consists of a former military campus area of 50 acres, which is currently being transformed into a new living district. Tests are being implemented on-site, in order to investigate and validate the good performance of recycled materials, coming from the demolition of old buildings which are processed also on-site and reused for the new building constructions of the Bayernkaserne and for the area’s soil rehabilitation.

The steps implemented in the site are the following:

- Cleaning of the construction site

- Design of selective renaturation with the greatest possible separation of the material

- Material preparation by breaking and sieving

- Production of recycled material (also on-site), two rounds of testing, firstly in the mixture and secondly, after the production of concrete, mechanical tests

- Construction

Thus, the recycling of concrete, containing aggregates made from 100% crushed mineral rubble, is applied at the moment in Munich, in the Bayernkaserne area, out of the great variety of raw materials that is generated, due to the demolition of the old military buildings that have been selectively dismantled.

The secondary raw materials that are generated and their uses are:

- Crushed mineral rubble as aggregate consisting of crushed concrete

- Crushed bricks, plaster, mortar, concrete

- Crushed mineral rubble as coarse aggregate

- Recycled fines (<2mm)

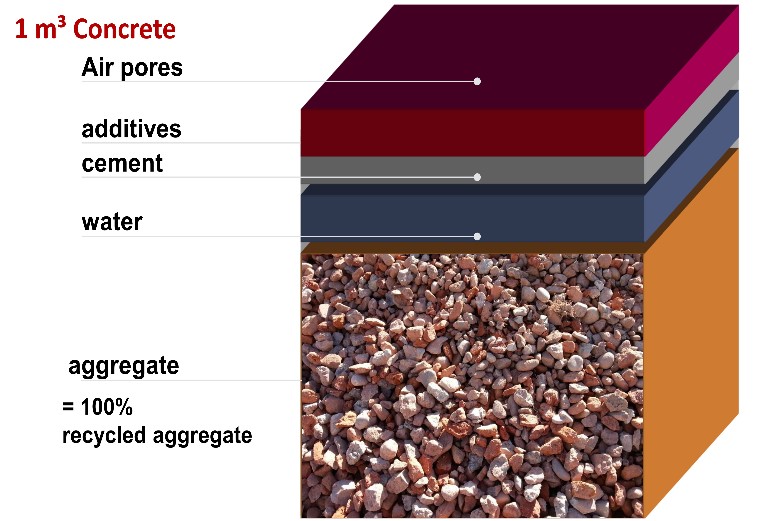

Newly produced concrete consists basically of the materials: depicted in Figure 3.

Figure 3: Synthesis of the concrete produced on-site (Source: Prof. Andrea Kustermann)

Optimisation is held in order to improve the workability of fresh concrete.

When optimal characteristics are achieved, fresh concrete is produced on-site, and precast elements are constructed.

The mechanical tests of the precast concrete elements, showed that the new materials are allowed to be integrated in the new constructions as parts of internal walls, granular subbases, ground plates, in an effort to recycle the mineral rubble as much as possible with quality of recycling concrete.

The results from the Bayernkaserne project, there are three areas of potential reuse of the materials:

- Buildings, following certain standards (i.e. DIN EN 206; DIN 1045; DIN technical report 100; DIN EN 12620; DIN 4226 T1 & T2)

- Earthworks and road construction, following: National guidelines; National ordinances; Technical contracts; Delivery conditions

- Gardening and landscaping, following specifications for large conurbations; apart from the production of concrete out of secondary materials, the soil is tested in the Bayernkaserne area and used for agricultural activities.

Although first results are positive, the whole process needs further laboratory testing.

Actions that URGE cities envisage to boost the introduction of new standards and update the EU and national regulation frameworks

The cities that participate in the URGE Network have identified the need to tackle the topics of standardisation, legislation, and procurements in order to boost circularity. According to the partners, actions that would have a big impact on the introduction of standards and regulatory framework, aiming to boost the use of secondary raw materials are depicted in the following infographic:

Infographic 2: URGE partners proposed actions to influence the standardisation and regulatory framework and boost the use of SRM in the construction sector (Source: Eleni Feleki)

A transnational thematic group has been built in the frame of URGE, dealing with the topic of use of secondary materials, enabled by technical specifications, standards and a regulatory framework. There is a lot of experimentation around concrete, soil and a lot to more to learn. Cities are interested in tackling the topics of standardisation and legislation boost green procurements, by developing integrated local action plans

Final remarks

Standardisation plays an important role in reassuring the safe (from any point, environmental, occupational health and safety) integration of secondary raw materials in the final products, replacing the virgin ones. Standards need to be reviewed/ updated or new should be designed, in order to introduce a European CDW Directive and enable the achievement of the ambitious EU targets concerning circular economy. Then, the adoption at national level by the MSs would also accelerated.

In some cases, existing environmental certification or rating systems for new buildings (such as Level(s) from the European Commission) can offer some guidance. Those systems usually include requirements to:

- Phase out hazardous substances from the construction products and materials

- Create a logbook that identifies all products used along with their placement in the building

- Sort out CDW in fractions enabling the reuse, recycle and material recovery

- Use construction products that include a specific percentage of recycled materials.

Certification systems can provide some valuable help. They can be very useful to stakeholders with limited experience and resources, providing them with detailed and tested criteria that can be directly implemented in procurement or control procedures. Stakeholders that find it difficult to research and produce their own criteria can take advantage of such systems. Another benefit is that those systems are updated in regular periods and always follow the improvements and the development of the building sector.

There is no doubt that there are additional restrictions that hamper the use of secondary materials. Lack of information about the life cycle of materials, their properties, their technical data, their quality and presence of hazardous substances, such as asbestos, the low price of price of virgin materials in relation to the processing costs of demolition waste to meet existing standards are only some of them. URGE will continue to seek for practices implemented among the participating cities and to exchange knowledge, in an effort to foster transnational dialogue among EU experts and stakeholders.

Acknowledgements

This article has been produced in the frame of the URGE APN, financed by the URBACT Programme.

All partners have contributed with input in the frame of the transnational exchange meeting, hosted digitally by the City of Munich.

Special thanks to the team from the City of Munich: Daniel Rank, URGE project coordinator, Department of Communal Affairs, Dr Gerhard Urbainczyk, Department of Communal Affairs, Barbara Bühler-Karpati, European Affairs Office, Department of Labor and Economic Development; Christian Brandes, Bavarian State Ministry for Housing, Building and Transport; Wichael Weiss, Demolition and construction company (Ettegruber) and DA Association; Prof. Andrea Kustermann, Munich University of Applied Sciences; Sebastian Knoll, senior expert in soil, Bodeninstitut.

External contributors: Konstantinos Litsios, Product specialist in The Nordic Swan Ecolabel, Argyrios Michalakis, Strucural Engineer- Project manager, Nikos Chatzivrettas, Civil Engineer-Project manager.

Submitted by Anonymous on